Technology

Vertical Combustor

Vertical Stoker Type Incinerator

High Performance and Low Environmental Impact with Our Proprietary 'SLA Combustion Method’

Stable Combustion without Fuel

Our proprietary 'SLA Combustion Method' enables efficient and stable combustion by converting waste into uniform combustible gas and carbonized material within the furnace (see diagram).

Waste is densely stacked inside the furnace, and a small amount of primary combustion air (λ = 0.5 or less) is introduced from the grate at the bottom of the furnace. As the waste moves downward by its own weight, it undergoes thermal decomposition, transforming into uniform combustible gas and carbonized material, allowing even heterogeneous waste to burn stably.

The combustible gas and carbonized material move in opposite directions within the enclosed space (combustible gas upwards and waste downwards), resulting in high thermal efficiency and extended residence time of the waste in the furnace.

The combustible gas that moves to the upper space is completely combusted with secondary combustion air, minimizing the generation of harmful substances. Meanwhile, the carbonized waste continues to burn and becomes ash, which remains in the furnace for an extended period, ensuring that any unburned materials in the ash are completely combusted over several hours. The incinerated ash is then discharged from the bottom of the furnace through our unique discharge mechanism.

The newly introduced waste is dried and thermally decomposed by the oxygen-deficient high-temperature reducing gas rising from the bottom of the furnace, allowing it to self-combust like fuel.

This process works not only for low-calorie waste with high moisture content but also for heterogeneous and high-calorie waste such as industrial and medical waste. The fluctuation in waste quality is always equalized within the furnace, eliminating the need for auxiliary burners during normal operation.

This versatility is why we refer to the Vertical Combustor as a "multi-fuel incinerator."

Additionally, compared to traditional moving stoker and rotary kiln furnaces, the Vertical Combustor has a simpler structure with fewer moving parts, particularly in high-temperature areas. This results in fewer breakdowns, shorter repair periods, and easier and quicker shutdowns, ultimately reducing operational and maintenance costs.

Suitable for various types of waste

No segregation is required

Robust to changes in waste quality

Sludge

~1,000 kcal/kg

(4.1 MJ/kg)

Municipal solid waste

~3,000 kcal/kg

(12.5 MJ/kg)

Industrial waste

~4,000 kcal/kg

(16.7 MJ/kg)

Infectious medical waste

~5,000 kcal/kg +

(20.9 MJ/kg +)

Flow diagram

Key features

-

Small, fixed amount of primary combustion air blown from furnace bottom uniformly passes through waste layer.

-

Fresh waste dropped on top of the waste layer with relatively high moisture content is not burned immediately, but is completely dried by the hot pyrolysis gas rising from the pyrolysis zone.

-

Since the primary combustion air ratio is low, a larger amount of secondary combustion air can be injected into the secondary combustion chamber to ensure efficient combustion of the flue gas to minimize the generation of pollutants.

-

Vertical Combustor incinerators can be operated automatically or manually using PLC/DCS.

-

The plant equipped with a vertical combustor can operate continuously for 24 hours or intermittently. It can be started up in just 30 minutes, resulting in lower fuel consumption. Additionally, there are no issues with flue gas treatment, even during the period from shutdown to the next start-up.

-

Thermal recycling can be achieved through power generation, steam/hot water production, or the utilization of absorption chillers. Since combustion remains stable, power generation from waste incineration becomes highly efficient, ensuring a consistent generation of steam.

Commercial advantages

-

The fed waste is combusted by the heat content of the waste itself, so no auxiliary fuel is required during normal operation. Auxiliary fuel such as heavy oil is used only during start up and shutdown of the plant.

-

All wastes of different characteristics and quality are converted into fuel (carbide and combustible gases) by pyrolysis process and then incinerated. Therefore, waste separation is not required.

-

Due to its simple structure and fewer moving parts, it is relatively easy to operate. A minimum of 3 people are required to operate the system.

-

Fewer mechanical problems because there are no moving parts in the high temperature zone, and the number of moving parts themselves is much less than the other types of incinerators such as moving stoker and rotary kiln incinerators.

-

Due to its vertical structure, the land area required is less than other types of incinerators.

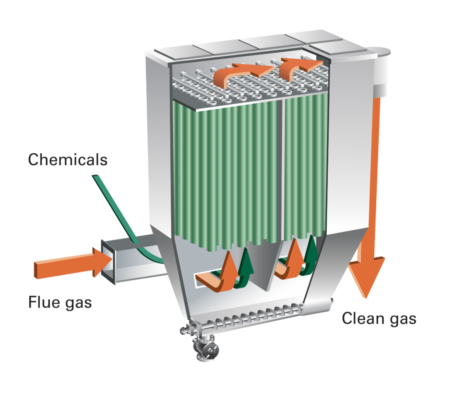

Turbo Chemical Baghouse

Dry Type Chemical Reaction Dust Collector

Cost-Effective Dry Processing with Efficiency Comparable to Wet Processing

Effective Elimination of Harmful Substances with a Thick Precoat Layer of Chemicals

Turbo Chemical Baghouse

Conventional Baghouse

Technical features & advantages

-

The thick precoat layer of chemicals (slaked lime and/or activated carbon) increases the contact efficiency between the chemicals and hazardous gases, so that the removal efficiency is equivalent to that of wet treatment such as water scrubber, even though it is a dry treatment. In addition, wastewater treatment is not required as in the wet process.

-

The thick precoat layer of chemicals formed on the filter cloth can reduce damage to the filter cloth caused by acid gas, thus extending the service life of the filter cloth.

-

High efficiency of contact between flue gas and chemicals reduces unreacted chemicals and chemical consumption. The reduction in the amount of chemicals used also reduces the amount of fly ash, which reduces not only the cost of chemicals, but also the cost of final disposal of fly ash.

-

The precoat layer ensures that dioxins, high concentrations of hydrogen chloride, sulfur oxides, mercury and other heavy metals, and other difficult-to-remove toxic substances can be reacted and adsorbed for removal. The flue gas emission standards of not only Japan, Singapore, and Indonesia, but also EU can be met by dry treatment only.

Watch video

Movies above are excerpts from the TV programs broadcasted on BS Japan.

Contact us

We’re always looking for new opportunities and are comfortable working internationally.

Please get in touch and one of our project managers will contact you about beginning the proposal process.

Plantec Asia Pacific Pte Ltd

Phone: +65 6222 1114

Email: info@plantec-ap.com

Address: 380 Jalan Besar, #10-01 ARC 380, Singapore 209000

Office Hours: 9 am to 6 pm on Monday to Friday